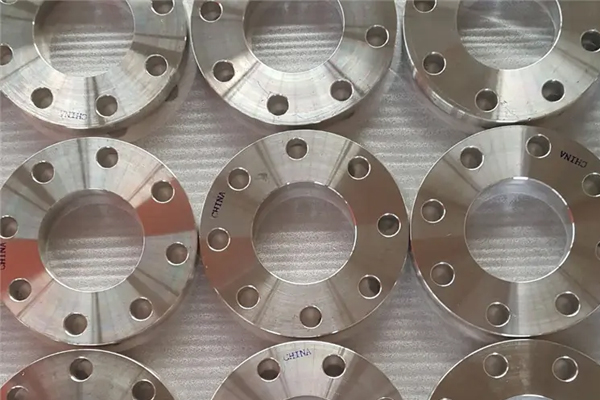

Flat welding flange forging method and matters needing attention

Flat welding flange according to your favorite forging die movement, it can be divided into swing rolling, swing rotary forging, roll forging, wedge rolling, ring rolling, cross rolling and so on. Precision forging can also be used in swing rolling, swing rotary forging and ring rolling. Roll forging and cross rolling can be used as pretreatment for slender materials to improve material utilization. Like free forging, rotary forging is partially formed and has the advantage of forming even if the forging force is less than the forging size. Complex forgings can be finished in one or more processes. Because there are no burr edges, the forging bearing area is reduced and the required load is reduced.

This forging method causes the material to expand from close to the flange when it is machined. Because the distance between the die surface and the free surface is different, it is difficult to guarantee the precision. Therefore, by controlling the movement direction of the forging die and the rotary forging process by computer, the products with complex shape and high precision can be produced. Yes, I can do it. Obtained with lower forging power. Steam turbine blades and other types and large size forgings manufacturing.

Flat welding flange forging can be divided into free forging, upsetting, extrusion, die forging, closed die forging and closed upsetting forging. In general, forging in the recrystallization temperature range is called hot forging, at room temperature without heating forging is called cold forging. When flat welded flanges are forged at low temperature, the dimensions of the forgings hardly change. When forged below 700℃, almost no oxide scale is formed and no surface decarburization occurs.

Flat welding flange sealing principle: the two sealing surfaces of bolts press on the flange gasket to form a seal, which may also lead to seal damage. In order to maintain the seal, it is necessary to maintain a large bolt force, so increase the bolt. Large bolts should match large nuts. This means you will need larger diameter bolts to create conditions for tightening the nut.

Note for flat welding flange

1. The steel plate used to manufacture flat welded flanges is manufactured and used through ultrasonic inspection without delamination, in order to identify good quality and performance problems, and manufactured and tested according to specific quality requirements, the steel plate does not have quality problems.

2. Steel is cut into strips along the rolling direction, and then bent and butt welded into rings, forming a circular surface on the steel. The cylinder. In the manufacture of flat-welded flanges, the steel plate should not be machined directly to the neck flange, but rather manufactured and machined using a specific technique.