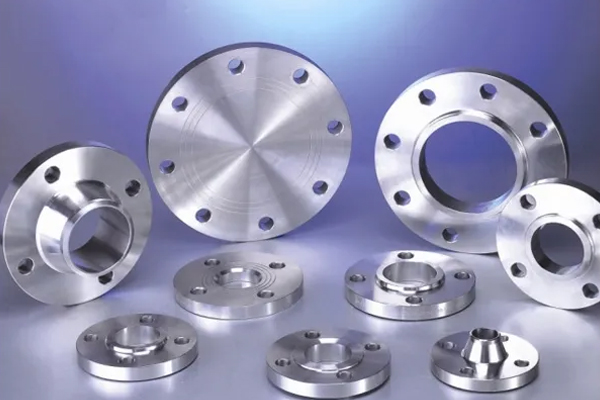

Stainless steel flange die forging equipment and application characteristics

The mechanical properties of the forgings are higher than those produced on the hammer. High productivity; Less metal loss; Hammer forging die is composed of two parts of the upper and lower die, horizontal machine is composed of punch and by two half of the composite of a total of three parts of the cushion, so it is possible to forge hammer forging forging can not manufacture; Accurate size, smooth surface.

Key points of forgings design of horizontal press die forging: Forgings in upsetting after should not interfere with the concave part of forging die separation; To have a slope; Have rounded corners; To avoid forging in the longitudinal section of the neck part, it prevents metal flow; To avoid the middle concave and tail taper; Flange shaft parts, when the length is equal to the diameter of 10-12 times, flange can not be greater than the volume of the shaft; The wall thickness of perforated forgings shall not be less than 0.15 times diameter.