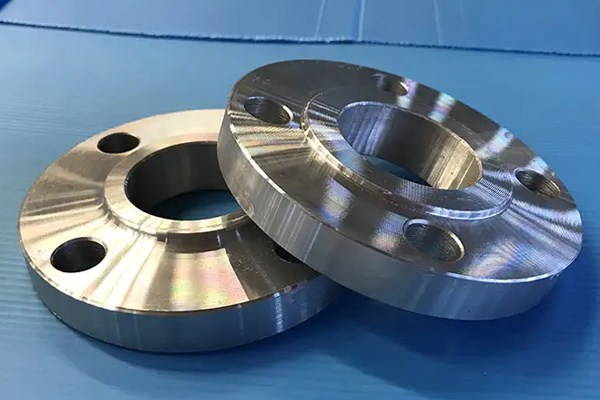

Flat welding flange manufacturers bring you to understand the flange corrosion problems

Flat welding flange manufacturers bring you to understand the flange corrosion problems

The direct external cause of flange and bolt corrosion is the existence of corrosive medium between the flange clearance, in the absence of anti-corrosion coating protection, flange metal surface and bolt directly contact with water and air will soon rust. Once took two flanges at the joint with adhesive tape or plastic pipe winding measures for a week, trying to prevent external moisture and sundries into the flange gap, the method to a certain extent can prevent sundries into the flange gap, but the anti-corrosion effect on the flange components is not big, after use found three aspects of the problem:

1. Due to the failure to achieve complete sealing, in a humid environment, there is still condensation water accumulated in the flange clearance due to the temperature difference. If it cannot be eliminated in time, corrosion will be accelerated.

2. a pair of flange clearance from the external closed, once the flange gasket leakage, easy to produce natural gas accumulation, not conducive to safe production.

3. After a period of use, the adhesive tape and plastic tube need to be replaced regularly due to the aging of the material.

Therefore, using adhesive tape or plastic pipe to seal the flange gap from the outside to carry out anti-corrosion treatment, the practical effect is not ideal, need to find a new anti-corrosion treatment technology and method of pipeline flange.