Methods for inspection of large forgings

Due to the high cost of raw materials for large forgings, as well as the production process, if defects occur, they will affect the follow-up processing or poor processing quality, and some affect the performance and use of forgings strictly, even reducing the service life of the finished parts, endangering safety. Therefore, in order to ensure or improve the quality of large forgings, in addition to strengthen the quality control in the process, take appropriate measures to eliminate the emergence of forging defects, but also should carry out the necessary quality inspection, to prevent the subsequent process with a bad impact on the performance of the defects of the forgings flow to the subsequent process. After quality inspection, remedial measures can also be taken to the forged parts according to the nature of the defects and the degree of influence on the use, so that they meet the technical standards or the requirements of use.

Therefore, forgings quality inspection in a sense, one side is the quality control of the forgings have been made, on the other hand is to point out the improvement direction to the forging process, so as to ensure that the quality of the forgings meet the requirements of the forging technical standards, and meet the requirements of design, processing and use.

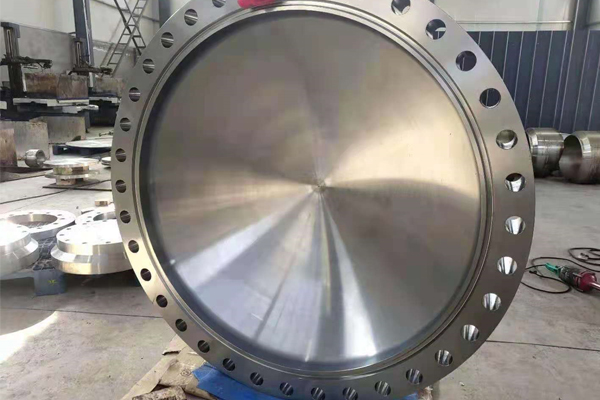

The quality inspection of large forgings includes the inspection of appearance quality and internal quality. Appearance quality inspection mainly refers to the inspection of the geometric size, shape, surface condition and other items of forging; The inspection of internal quality mainly refers to the inspection of chemical composition, macroscopic structure, microscopic structure and mechanical properties of forgings.

Because of forgings made parts, the stress distribution in the process of use, the important degree, the working condition is different, its materials and metallurgy process is different, so different department based on the above situation and according to the requirements of this international lang door will forgings to separate categories, different departments, different standards for the classification of the forgings are also different. In any case, for the quality inspection of large forgings as a whole are inseparable from two categories of inspection, that is, the inspection of appearance quality and internal quality, but the types of forgings are different, and the specific inspection items, inspection quantity and inspection requirements are different. For example, some industrial departments will be structural steel, stainless steel, heat-resistant steel forgings into IV class for inspection, some departments will be aluminum alloy forgings and die forgings according to their use into class for inspection, and some departments will be aluminum alloy, steel alloy forgings into IV class for inspection.