The sealing method of hydraulic cylinder forging

The reason why the hydraulic cylinder forgings need to be sealed is because of the existence of internal leakage and external leakage. When there is internal leakage and external leakage in the hydraulic cylinder, it will lead to the volume of the hydraulic cylinder's cavity and the efficiency will become smaller and the performance of the hydraulic cylinder will be reduced in the work. When the situation is serious, the system will not be able to work under pressure. At the same time, from the perspective of environmental protection, leakage should be avoided as far as possible, so it is very important to take the necessary sealing measures.

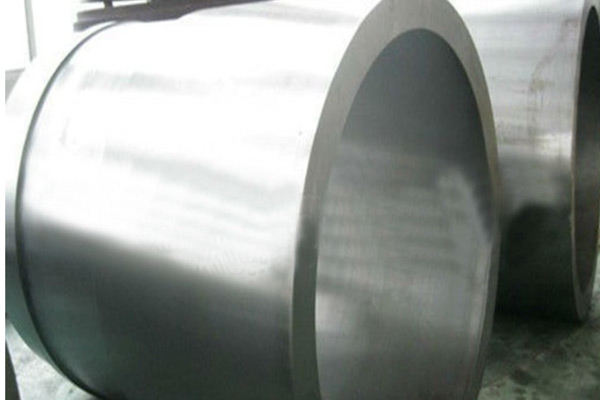

The main sealing parts in the hydraulic cylinder are piston, piston rod, end cover and so on. And there are three ways of sealing the hydraulic cylinder. Today, Jiuli will introduce the three ways of sealing the hydraulic cylinder:

First, clearance sealing

Its working principle is that there will be a little gap between the two moving parts, and the liquid friction resistance generated in the gap will prevent leakage. This method has some disadvantages, is only applicable to small hydraulic cylinder and the piston diameter and pressure between seal and advantage in order to improve the efficiency of the seal will leave a few groove on the piston, the groove will let the oil change in internal leakage path or truncate, in a small groove form vortex and produce resistance, and reduce the oil leakage; On the other hand, it prevents the offset of the piston axis, which is conducive to maintaining the fit clearance, ensuring the lubrication effect, reducing the wear of the piston and the cylinder wall, and increasing the clearance sealing performance.

Two, the use of rubber sealing ring

Because of the different types of sealing rings in hydraulic cylinder forgings, the sealing mechanism used is not the same, and the O-type sealing ring mainly relies on the amount of pre-compression to offset the gap to achieve the sealing effect. And Y, YX, V shape, etc., rely on the sealing ring lip deformation by the action of liquid pressure, so that the lip close to the sealing surface and seal, the higher the liquid pressure, the more tight the lip stick, and has the ability of automatic compensation after wear.

Three, the use of rubber sealing components to achieve sealing effect

This kind of seal is generally a combination type with the characteristics of two kinds of seals, which play a sealing role together in the work. Take a greyring, which is a combination of a rubber O-ring and a teflon greyring. In the work, the good elasticity of O-type rubber ring produces pre-and self-moistening, so that it can be used in the hydraulic cylinder seal longer life.

The above is the specific sealing way of the hydraulic cylinder, I hope it will be helpful to you.