What are the uses of forgings?

Forgings are workpiece or blank obtained by forging deformation of metal billets. The mechanical properties of metal billets can be changed by applying pressure to produce plastic deformation. Forgings can be divided into cold forging warm forging and hot forging according to the temperature of the billet during processing. Cold forging is generally processed at room temperature, while hot forging is processed at a recrystallization temperature higher than the metal billet.

1, general industrial forgings, refers to the machine tool manufacturing, agricultural machinery, agricultural tools manufacturing and bearing industry and other civil industries.

2. Forgings for hydrogenerator, such as spindle and intermediate shaft, etc.

3, power plant forgings, such as rotor, impeller, ring spindle, etc.

4, metallurgical machinery, such as cold roll, hot roll and miter gear shaft, etc.

5, forgings for pressure vessels, such as cylinder, kettle ring flange and sealing head.

6, Marine forgings, such as crankshaft, tail shaft, rudder shaft, thrust shaft and intermediate shaft, etc.

7, forging mechanical equipment, such as hammer head, hammer rod, hydraulic press column, cylinder block, wheel and shaft press machine pillar and cylinder block.

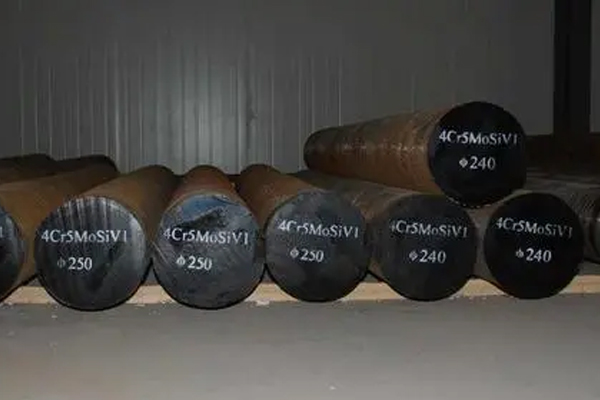

8. Module forgings are mainly forging dies for hot die forging hammer.

9, the automotive industry forgings, such as left and right knuckle, front beam, coupler, according to statistics in the car, forgings account for 80% of its quality.

10. Forgings for locomotives, such as axles, wheels, plate springs, crankshafts of locomotives, etc. According to statistics, forgings account for 60% of the quality of locomotives.