What is the process of forging?

1. Isothermal forging is to keep the temperature of billet constant during the whole forming process. Isothermal forging is used to take advantage of the high plasticity of certain metals at constant temperature or to obtain specific structures and properties. Isothermal forging requires the mold and billet to be kept at a constant temperature together, which requires a high cost and is only used for special forging and pressing processes, such as superplastic forming.

2. Forging can change the metal structure and improve the metal performance. After hot forging the ingot, the original cast state of loose, pore, micro crack is compacted or welded; The original dendritic crystal is broken to make the grain fine. At the same time, change the original carbide segregation and uneven distribution, so that the organization is uniform, so as to obtain internal dense, uniform, fine, good comprehensive performance, reliable use of forgings. After hot forging deformation, the metal is fibrous structure; After the cold forging deformation, the metal crystals show order.

3. forging is to make the metal plastic flow and made into the desired shape of the workpiece. The volume of metal is unchanged after plastic flow by external force, and the metal always flows to the part of least resistance. In production, the shape of the workpiece is often controlled according to these laws, and the deformation of upsetting drawing, reaming, bending and deep drawing is realized.

4. the forging workpiece size is accurate, conducive to the organization of mass production. Die forging, extrusion, stamping and other applications of the mold forming size is accurate and stable. High efficient forging machinery and automatic forging production line can be used to organize specialized mass production or mass production.

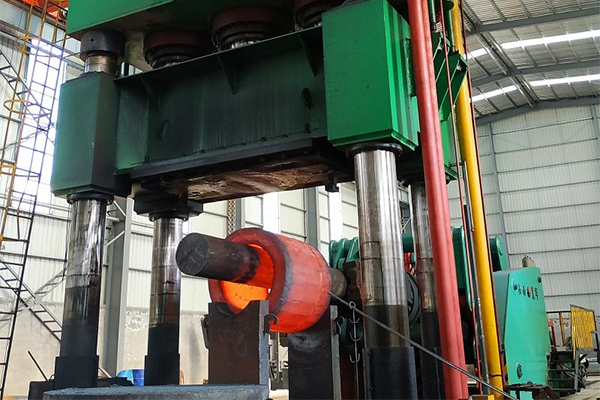

5. The production process of forging includes blanking, heating and pretreatment of forging blank before forming; Heat treatment, cleaning, calibration and inspection of workpiece after forming. Commonly used forging machinery has forging hammer, hydraulic press and mechanical press. Forging hammer has a large impact velocity, which is conducive to metal plastic flow, but it will produce vibration; The hydraulic press uses the static forging, is advantageous to the forging through the metal and the improvement organization, the work is stable, but the productivity is low; The mechanical press has fixed stroke, which is easy to realize mechanization and automation.

In the future, the forging technology will improve the internal quality of forging parts, develop precision forging and precision stamping technology, develop forging equipment and forging production line with higher productivity and automation degree, develop flexible forging forming system, and develop new forging materials and forging processing methods. To improve the internal quality of forgings, it is mainly to improve their mechanical properties (strength, plasticity, toughness, fatigue strength) and reliability. This requires better application of metal plastic deformation theory; Apply intrinsically better quality materials; Correct pre-forging heating and forging heat treatment; More rigorous and extensive nondestructive testing of forgings.